Taking VAC-V1 as an Example to Discuss How to Improve Testing Efficiency of Gas Permeation

Comparing with other property testing of flexible package, permeability testing takes a rather longer time. This is especially true in the testing of high permeability materials. Low efficiency of permeability testing will decrease the comprehensive analysis speed of specimen, which in turn will influence productivity. Therefore, test failure resulted from human error must be reduced as far as possible. This can be realized through the standardization of operation.

Based on the practical applications of VAC-V1, this article deals with how to improve testing efficiency of gas permeation instruments of differential pressure method.

1. Specimen Examination

All the indexes of specimen should be examined according to corresponding standard. Whether a specimen can be adopted is specified in corresponding standards. As to gas permeation testing, it is important to choose specimen with good surface condition. Creases and pinholes existing on the specimen will influence testing data and even cause test failure.

The Specimen should be representative, and its thickness should be even and unanimous. In different testing standards, descriptions of specimen may be slightly different. Operator should collect and make specimen completely according to the executive standard. Moreover, they should observe the specimen condition carefully to avoid testing failure caused by selecting error of specimen.

2. Apply Vacuum Grease

Apply vacuum grease on the non-gas-transmission area of lower testing chamber before placing the sample. This procedure is of critical importance in the process of specimen clamping. Vacuum grease has two functions: prevent edge leakage of specimen, and furthermore, level the lower testing chamber during specimen clamping. Vacuum grease must be applied carefully. Do not pollute the testing area when applying grease. Otherwise it will influence the testing result to some extent. Primary users can finish the applying process with ester spread ring.

Vacuum grease should be applied evenly in case it may affect the condition of specimen in testing area or made specimen wrinkle when upper and lower testing chambers joint each other, which may affect sealing effect of the whole testing system. In addition, applying quantity should be proper. Excess vacuum grease may cause vacuum grease waste and testing environment pollution and lack of it may influence sealing effect and result in testing failure.

3. Place Filter Paper

The purpose of setting filter paper in differential method is to realize the support function. Since the two sides of specimen have a differential pressure of 0.1Mpa, specimen will appear shape deformation to some extent. To avoid testing error caused by specimen damage, filter paper must be set according to the operation guidance strictly. Keep the filter paper clean and dry and do not make it contact vacuum grease or depart the specified position during setting. Otherwise testing result will be influenced and testing efficiency will be decreased.

4. Place Specimen

Whether specimen is placed in the center will directly influence the sealing effect of edge O-rings in testing chamber. As is known, edge leaking of specimen will influence the whole permeation process and the influence is especially obvious to complex film. Labthink VAC-V1 has two seal rings designed specifically for edge sealing. But to achieve good sealing effect, specimen must be placed in the center of lower chamber. The special localizer loop of VAC-V1 can efficiently solve the problem of specimen placement and make the operation simple and convenient.

5. Clamp Specimen

Labthink VAC-V1 uses the rotating and clamping of lead screw to clamp specimen. After placement of the specimen, rotate the handwheel to joint upper and lower chambers. In this way, specimen clamping is finished. Unique design of positioning guidance has reduced human error during the joint of upper and lower chambers with higher efficiency and convenience.

6. Testing Curve

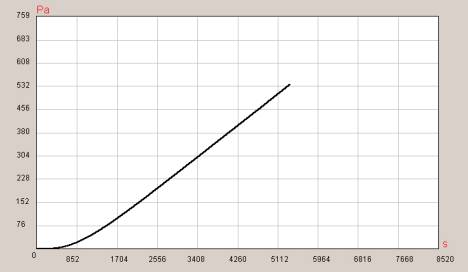

VAC-V1 software can facilitate testing process observation of operators. By observing testing curve, operators can judge whether there are any problems, such as the existence of crease or pinhole. If the specimen really has defects and has not been discovered by operator during specimen preparation, the test should be ended as soon as possible and replace qualified specimen for new tests. Otherwise, not only testing time and resource is wasted, testing results obtained may also be misleading.

Fig.1. Testing Curve of PC Film

7. 24-hour Continuous Testing

Permeation testing needs a real time observation by operators. If there is any abnormal condition, it must be checked immediately to prevent accident. Compressed air resource and instrument stability are the main sources of problem. VAC-V1 has a stable performance and can run for a long time. If compressed air is in proper condition and other factors that may cause problem is examined, the instrument can test for a long time and greatly improve testing efficiency.

8. Temperature Controlling of Testing Chamber

Labthink VAC-V1 has an excellent function of temperature controlling, which can maintain the chamber temperature under specified value steadily and prevent adverse effect on testing caused by temperature fluctuation. Numerous tests have proved that steady temperature can improve data stability and testing efficiency effectively. Data fitting function of VAC-V1 can be used to calculate permeability parameters under any temperature through the data of more than two groups obtained under different temperature. This method has a higher accuracy and is the feasible method for obtaining permeability parameters rapidly under special temperature.